Tips for Choosing the Best Kershaw Hunting Knife

27th Jan 2021

Kershaw is not a brand that typically conjures up images of hunting knives or even fixed blades. Knife collectors and outdoorsmen know that Kershaw’s bread and butter lies in folders. Many Kershaw folders are designed for EDC (everyday carry) or tactical purposes, but that doesn’t mean you shouldn’t throw Kershaw in the running for a hunting knife. A Kershaw hunting knife can be your best mate in the field. You just need to make sure you cover a couple ground points before you pick it out.

Choose a fixed Kershaw hunting knife

Admittedly, Kershaw has produced some really groundbreaking innovations in folding knife technology. Some of the following reasons are why Kershaw knives are predominantly thought of as folders.

-Strong locks: Kershaw folders are iconic for offering a quick, sure lock up that is reliable. Many of their folders are made with frame locks or liner locks that allow for no play in the blade when it is locked, and readily disengage when you want them to, without failing. This makes them reliable and convenient for people looking to keep a handy blade on them at alll times.

-SpeedSafe Assisted Opening: Many Kershaw folders also make use of their legendary SpeedSafe Assisted Opening mechanisms. They open in a flash and provide the sure lockup already mentioned. In addition, many of them open via the aid of a flipper mechanism that is both ergonomic and practical.

-Composite Blade Technology: Kershaw was also one of the first knife makers to take an old practice and make it “new” again with modern marketing. Their composite blade technology makes use of more than one steel and sometimes affords a differential heat treatment so that you can get the benefits of toughness and edge retention. It results in a blade that is hard enough along the edge to last for a long time while soft and tough enough along the spine to tolerate hard use.

-Tough materials: Kershaw blades are also made from a variety of stainless steels that resist corrosion as well as other materials like synthetic and aluminum handles that make them practically impervious to the elements. They are light and strong - and that’s a big selling point in a tool.

However, some of these features are not desirable in a hunting knife. Sure, you can carry a folder in the field as a backup knife, but when your hands are cold, you’re covered in grease or blood, or you’re going to really buckle down on a blade, you probably don’t want to rely on a folder.

A strong lock is great, but it’s still a failure-point in a knife. Without a lock, there is no lock to fail. That also invalidates the need for technology like their SpeedSafe Assisted Opening. An argument for it is that it allows for one handed opening - but remember, a fixed blade also only requires “one-handed operation” by its very design.

Generally, the work involved in hunting, that is, carving shooting lanes, making impromptu tools, skinning, gutting and breaking down game, means that a fixed blade Kershaw hunting knife would probably be much more useful in most circumstances than a folder. You should definitely carry a second knife with you in the field, and by all means, make it a folding Kershaw knife, but you’ll probably want a fixed blade for your go-to knife.

There’s more to quality in a hunting knife than being fixed. The blade profile matters too. Here are some things to look for in a hunting knife if you can find them.

Blade profile matters

Blade profile, like steel chemistry which we will discuss below, is one of the most important things you can account for in a hunting knife. Here are some of the most useful patterns aligned with the situations and circumstances for which they are most practical.

Drop point blades: Drop point blades are some of the most popular blade profiles among hunting knives, Kershaw and otherwise. They are very sturdy, can handle tough work, and are extremely reliable. If anything, a drop point blade is probably the strongest type of tip design there is (except maybe a tanto point) because there is a lot of steel behind the point. The one drawback is that the somewhat “stout” point of a drop point knife will give you a little less dexterity. These types of knives can be made with a swept belly to be useful for skinning while still being stout enough for boning and separating joints.

Clip point blades: Clip point blades were once more popular than they are today but they are still popular for hunting. Clip point designs are popular among classic hunting knives like Buck’s infamous 119 and many Case hunting knives and bowies. They have all of the benefits of drop point blades with one distinct advantage and one disadvantage that should be noted. On one hand, a clipped blade allows for the highest degree of precision with a hunting knife because the points are so narrow. On the other hand, they are more prone to breakage.

Trailing point, AKA swept point blades: Trailing point knives, also known as swept point knives, are very useful for skinning and slicing, but other than that they have somewhat limited utility. The specialization of the style does take away, in part, for their overall usefulness, but a knife with a swept blade is highly useful for the tasks described above.

Straight back blades: Straight back knives are general all purpose tools, combining some of the strengths of a clipped point with the strengths of a drop point. Knives made by Mora and Martiini frequently have straight backs; iconic designs like the Puuko are known for this. A knife with a straight back isn’t going to be likely to win any beauty pageants, but as a rule, they are tough, dependable, and highly useful for general purposes.

Spear point blades: Spear point blades have a place in hunting, whereas their close relative, needle-pointed blades, lack enough general utility to be of much use. Needle pointed blades and stilettos are good for just about one thing and one thing only: piercing. You just won’t need to do enough of that as a hunter for it to really be useful.

Spear point knives, on the other hand, are highly useful as hunting knives. Like straight backed knives, they’re good all-purpose tools. Unlike straight backed knives, spear point knives have a finer point to work with. In this respect, think of them almost as a variation on a drop point, but with a slightly weaker tip.

What type of steel?

In addition to the blade profile, the type of steel you choose in your Kershaw hunting knife will make a huge difference in the performance of the tool. As a general rule, Kershaw uses stainless steel alloys, but just saying “stainless” really doesn’t mean anything. Here are some of the steels you will find in Kershaw knives, along with their relative attributes.

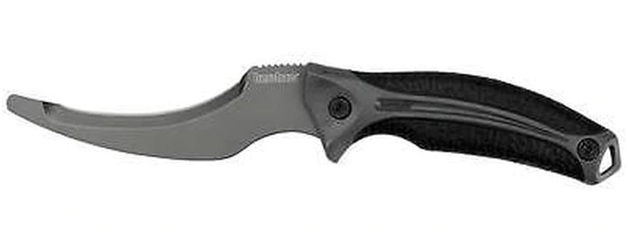

●8Cr13MoV: 8Cr13MoV is a very popular steel among modern knife makers because it is cheap to produce and can produce a middle of the road knife. With a little care and attention an 8CrMoV steel blade will serve you well. It has been compared to AUS-8, but the reality is that it is a little bit softer and not as tough. This grade of steel can take a nie edge, but it will not hold it very long. On the upside, it’s not prone to shattering and it is fairly corrosion resistant. The Kershaw Fixed Tone to the left has an 8Cr13MoV blade - as do many others.

●D2: D2 is a marvellously tough tool steel that is often used in larger fixed blades. Some of the Kershaw camp knives are made with D2 steel. Very tough and able to take a ridiculously sharp edge that it will hold for a decent length of time, D2 is great in all aspects except one: it is not very corrosion resistant.

●CPM 154: CPM 154 is a version of CM154 that has a suite of desirable features. For one thing, being a crucible power metallurgy steel, CPM 154 can be treated to produce a very hard steel. That makes one of its prime traits the ability to hold an edge for a long time. It’s hard, somewhat corrosion resistant and relatively tough, but the edge (no pun intended) goes to hardness. It’s not an alloy that you’d want to bang on for fear of breaking it, but for a hunting knife that has to cut through skin and hair, it might make a good choice.

●420HC: 420HC is an everyman’s budget steel that is cheap to produce and easy to work. Because of these two features it is very popular among knifemakers and many budget knives (including Kershaw’s) are made with it. It has limitations, but it doesn’t deserve the bad rap that some collectors and knife users have given it. It can be heat treated to produce a relatively hard steel that will hold an edge for a decent length of time. Also, when treated properly, it’s not prone to shattering - but that doesn’t make it 1045 so don’t baton with it. It’s relatively tough (not like D2) and all things considered, is most similar to 8Cr13Mov listed on here. If it’s good for one thing, it’s this: 420HC might be the most corrosion resistant steel we’ve mentioned yet.

●Sandvik 14C28N: Sandvik has produced some very fine steels over the years and many of Mora’s knives make use of them. This particular alloy makes use of carbon (of course) manganese and silicon, as well as chrome and nickel. These additives, together, make this steel hardenable, fairly tough and relatively corrosion resistant. Think of it, if you will, like a higher performance version of 420HC with relatively similar resistance to corrosion. The main difference is this Sandvik is a little bit tougher and can be given a really good heat treatment for edge retention

●S30V - Some users consider S30V to be a super steel, one that violates that maxim that you can have two of the three qualities of good steel, being hardness, toughness and corrosion resistance, but never all of them. Kershaw makes a variant of their perennially-popular Blur in S30V. This steel alloy is a sintered steel with almost 1.5% of carbon for hardness and edge retention, along with vanadium carbines for hardness and additional toughness. Now, this alloy gets top scores for corrosion resistance and edge retention, but though it is very tough, some alloys like this can break if really stressed. That makes them questionable as camp knives, but for hunting and EDC, you’ll probably love it.

Now, one thing we’d like to note is that some of the steels we have mentioned above only come in Kershaw folders on our website, so if you’re looking for the strength of some of these types of steels you may have to relegate the knife to a backup or go with a different brand. However, you can find Kershaws on our site - either in fixed or folding models - that have featured the alloys mentioned here.

Still Have Questions? Call Us!

Do you feel like you’re ready to pick out your next Kershaw hunting knife or would you still like a little more information before proceeding. Buy a good knife and take care of it and it will last you a lifetime, and there’s no reason at all that this purchase should be any different.

Take a look through our online collection of hunting knives from Kershaw and many other enduring manufacturers, and if you have remaining questions about steels, blade profiles, knife care or anything else, we’re your source - get in touch with us.

You can reach us at WhiteMountainKnives@gmail.com, which reminds us, there’s one more thing you should know. If you already have a model of Kershaw in mind and you can’t find it on our website, send us an email to see if we can find it for you. We have a huge vendor network and for the benefit of our customers, that means we have access to stock that isn’t currently listed on our website.